GATHER Turbine pump

The magnetically coupled process pump

The magnetically coupled process pump

-

1. Magnetic coupling – hermetically sealed

Wear- and maintenance-free without any leakage of the pumped medium

More details -

2. Pulsation-free delivery & dosing

Speed-dependent delivery characteristic with practically pulsation-free flow rate

More details -

3. Non-lubricating liquids

Use of chemically resistant and high-precision manufactured pump materials (stainless steel, Hastelloy®, titanium, etc.)

More details -

4. Cooling magnetic system & slide bearings

Internal flushing channels and holes for cooling the magnetic system and lubricating the slide bearings (sliding film)

More details -

5. Robust design and long service-life

…by using magnetic coupling, internal circulation, precise manufacture and double-volute pump construction

More details -

6. Low-noise operation

Low-noise operation due to construction type. Noise development almost limited to engine noise

More details

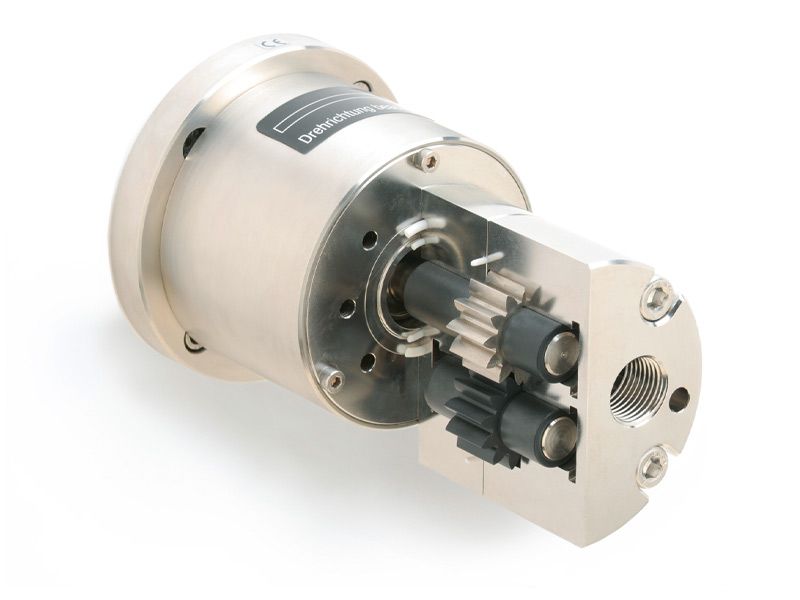

GATHER Industrie GmbH’s magnetically coupled mini turbine pump is a modern process pump for the pulsation-free metering, conveying and circulating of water, salt solutions, acids, alkalis and solvents, amongst other things.

With four different geometrical variants, flow rates ranging from 20 l up to 3600 l per hour can be attained at differential pressures up to 5 bar (see also operating data and flow rate characteristic diagram). Similar to the gear pump, it has internal wash borings and channels for efficient cooling and fluid circulation.

The magnetic coupling ensures a contactless torque transmission from the drive to the pump shaft. It is not subject to wear and tear and is absolutely maintenance-free. Together with its established slide bearings technology and simple design, the GATHER turbine pump represents a cost-effective, robust multi-purpose pump which is extremely quiet in operation.

-

1. Magnetic coupling – hermetically sealed

Wear- and maintenance-free without any leakage of the pumped medium

More details -

2. Pulsation-free delivery & dosing

Speed-dependent delivery characteristic with practically pulsation-free flow rate

More details -

3. Non-lubricating liquids

Use of chemically resistant and high-precision manufactured pump materials (stainless steel, Hastelloy®, titanium, etc.)

More details -

4. Cooling magnetic system & slide bearings

Internal flushing channels and holes for cooling the magnetic system and lubricating the slide bearings (sliding film)

More details -

5. Robust design and long service life

…by using magnetic coupling, internal circulation, precise manufacture and double-volute pump construction

More details -

6. Low-noise operation

Low-noise operation due to construction type. Noise development almost limited to engine noise

More details

Characteristics

- 1. Magnetic coupling – hermetically sealed

- 2. Pulsation-free delivery & dosing

- 3. Non-lubricating liquids

- 4. Cooling magnetic system & slide bearings

- 5. Robust design and long service-life

- 6. Low-noise operation

GATHER Mini turbine pump

At a glance

The magnetic coupling ensures contactless torque transmission from the drive to the pump shaft. Unlike mechanical seals, it is not subject to wear and tear and is absolutely maintenance-free. It is hermetically sealed and there is no leakage of the pumped medium. This is a decisive factor, especially with concentrated, aggressive media and those that are hazardous to health. In addition, it allows easy pump head replacement in practice.

Due to the operation of the turbine pump, a pulsation-free, flexibly adjustable flow rate can be attained. The speed-dependent delivery characteristic enables a wide flow rate range with differential pressures up to 5 bar. With four geometric variants, flow rates can be attained within operating ranges between 20 and 3600 liter per hour.

Operation with non-lubrication liquids is made possible, amongst other things, by using chemically resistant and high-precision manufactured materials. The pump body and shafts are made of stainless steel, Hastelloy® or titanium, the slide bearings e.g. of carbon or plastic. The range of viscosities is between ν = 0,3 mm2/s to 100 mm2/s.

Internal flushing channels and holes convey a small part of the flow from the delivery side through the slide bearings and back to the suction side. This leads to the internal cooling of the magnetic system and the slide bearings. In addition, the necessary sliding film is created on the slide bearings which ensures a durable functionality.

The use of the magnetic coupling, the internal cooling system, the pump concept and the high precision of the components result in a very robust design with an extremely long service life. Depending on the application (medium) the pumps operate maintenance-free.

Due to its construction type, the pump is characterized by low-noise operation. The noise development is almost limited to the engine noise.

GATHER Turbine pump

Operating data at a glance

| Characteristic | Property | |

|---|---|---|

Materials housing & shafts | Stainless steal, Hastelloy®, titanium and special alloys | |

Media | Non-lubricating and lubricating liquids | |

Viscosity | ν = 0,3 mm2/s up to 100 mm2/s resp. from 90°C hot water up to concentrated caustic soda (50%) | |

Flow rates / pressure | see flow rate characteristics | |

Series 1 | 20 – 300 l/h up to 2,5 bar | |

Series 2 | 60 – 1.000 l/h up to 3,0 bar | |

Temperature | T = -5 up to +100°C | |

Explosion classes | Locations 1, 2 und 22, temperature classes T1 … T6 resp. 100 K below glowing temperature of dust deposits (location 22) | |

Cleaning | Cleaning in Place (CIP) |

Flow rate characteristics

Downloads

Further information on key figures, technical details and instructions can be found in our download area.

Do you have any questions about GATHER‘s turbine pump?

GATHER Industrie GmbH

Lise-Meitner-Straße 4

42489 Wülfrath

GERMANY

Products

About Us