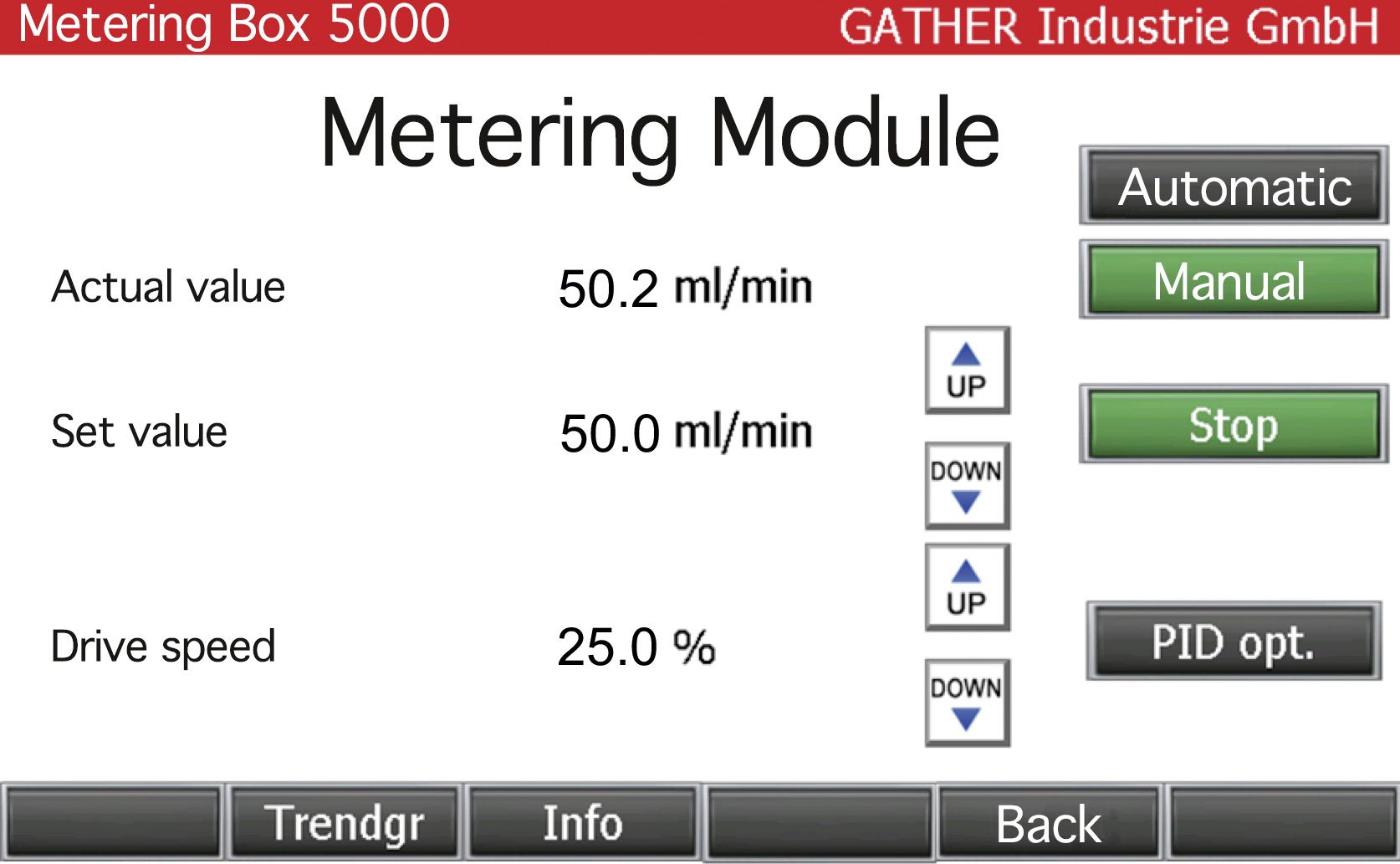

GATHER Metering box 5000

The universal controller for all pump and control loops

GATHER’s Metering box 5000 with integrated, universal PLC enables exact conveying, metering or filling at the touch of a button. It is suitable for all applications where pumps are operated in a loop system.

Your advantages at a glance:

-

Easy to use interface and handling (“Plug and Play”)

-

No programming skills required

-

Automated tuning for determining the control parameters (PID)

-

Easy integration into any control circuits, applicable to all dosage tasks and measuring systems

-

Both continuous metering and batch filling possible

-

Functionality independent of liquid viscosity

-

Integrated “master-slave-function

-

Applicable to all pumps (with pulsation-free delivery characteristics)

-

Special interfaces on request

Control loop / measurement system:

-

volume flow (e.g. MID, Turbine)

-

mass flow (Coriolis)

-

pH-value

-

pressure

-

gearwheel meter

Only two requirements for the pump:

-

pulsating free characteristics

-

variable speed drive

Standard inputs and outputs Metering box:

-

Inputs: 2x analogue (0-10 V, 2-10 V, 0-20 mA or 4-20 mA) and 2x digital (impulse and start/stop)

-

Outputs: 2x analogue (0-10 V, 2-10 V, 0-20 mA or 4-20 mA) and 2x relay

-

Electrical connection: 1x 230 V, 50-60 Hz

Do you have any questions about our GATHER Metering box 5000?

GATHER Industrie GmbH

Lise-Meitner-Straße 4

42489 Wülfrath

GERMANY

Products

About Us